Optimize your SOLIDWORKS Software setup:

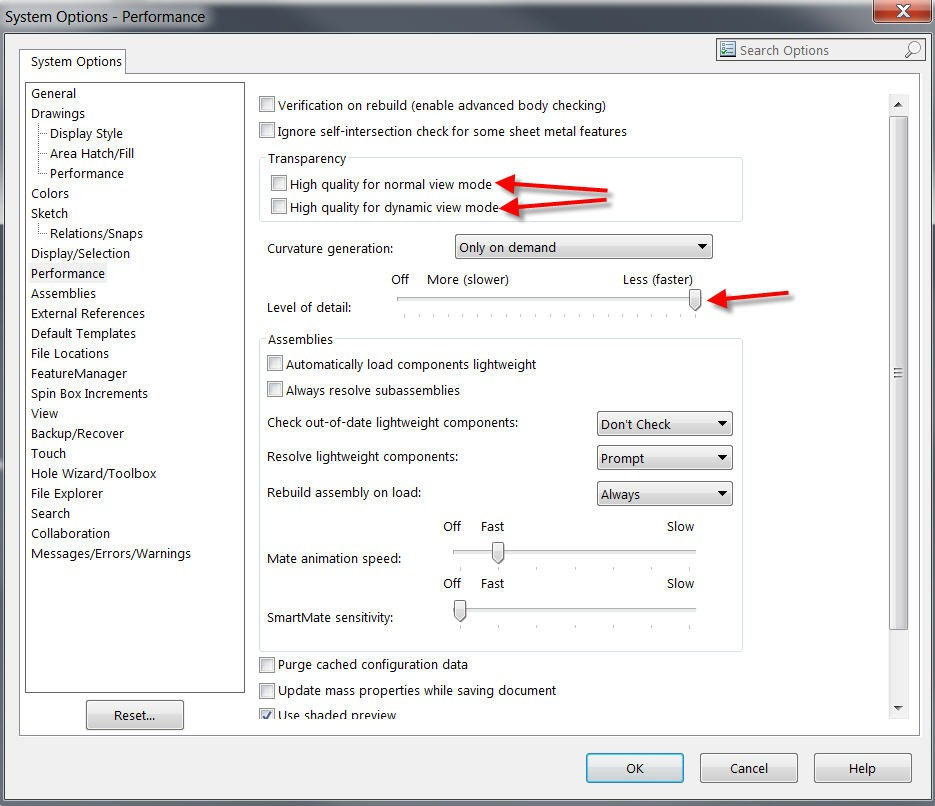

The best way to immediately impact large assembly performance is to setup SOLIDWORKS software correctly. Under the “Tools” menu select “Options” and under the “Performance” tab there are several options to improve performance

1. Turn off high quality transparency

2. Decrease the level of detail for curvature generation as shown in the figure below

SOLIDWORKS System Options: Performance

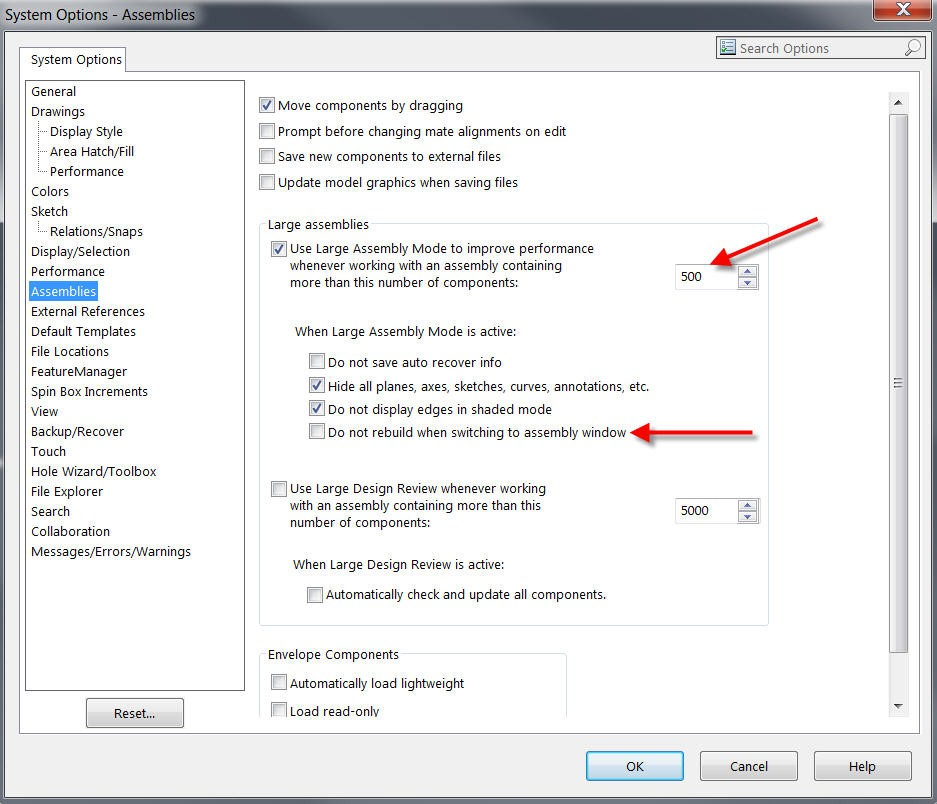

Under “Assemblies” you will find the “Large assemblies” section. The first option defines how many components are required before SOLIDWORKS goes into large assembly mode. If you are on a less powerful hardware you may want to lower it down to force SOLIDWORKS to go into large assembly mode with fewer components.

The next option here which has a great effect on your machine performance is the “turn off edges in shaded mode” option. This turns off all the little black edges on the parts. HUGE savings on your graphics card with many parts or even a few complicated castings etc.

SOLIDWORKS System Options: Assemblies

Avoid large assemblies

The best piece of advice that I can give is to avoid large assemblies and what I mean by that is to avoid putting a lot of parts and assemblies into one single assembly. Make sure you take advantage of using sub-assemblies and sub-sub-assemblies.

Use Configurations

Take maximum advantage of configurations. When working with models that can be complex or represented a simple part remember you could just make a configuration for each.

Constrain and define

The fourth tip is to confine and constrain every single thing in the model. It has been seen that designers leave several components unconstrained in their assembly because they want to drag them around. That may be great to showing the model to other people but it is very taxing on the software when you are trying to work in the model. The reason is every time you move or reopen something SOLIDWORKS will rebuild and recalculate the position of those components.

How can the load time for a large assembly be decreased?

Here are a number of tools which can be used to help load assemblies faster such as Large Assembly Mode and Lightweight.

Another tool which can be used is to create a display state and hide all the unnecessary components (like fasteners and other hardware) or hide assembly components which might be obscured (like the inner contents of a heat exchanged which cannot be seen because of the sheet metal housing) After creating this display state, in the open dialogue box, enable “do not load hidden components”.

Hardware Requirements :Click Here

To get more updates on SOLIDWORKS Follow Us on LinkedIn: Click Here

For more details Like Us on Facebook: Click Here

For videos SUBSCRIBE to our channel: Click Here

For more information: Click Here